Acid Flushing to remove "Hot Spots"

Roll Technology has been providing acid cleaning services with heat transfer roll applications for over 20 years. Most of the rolls are clogged with calcium due to poor plant/city water or older rolls where the filtration system has become less effective.

When heat transfer rolls (both heating and cooling) are having problems keeping a consistent temperature across the face and your web is sticking to the roll (commonly called having "hot spots") internal vibratory acid cleaning could be the solution.

Inhibited acid cleaning is best used to remove common deposits that buildup in the flow channels of heat transfer rolls, thereby affecting the temperature variation across the roll face. Our process incorporates a vibrating sequence to further loosen internal impediments. We utilize high-speed pumps and measure GPM flow readings before and after cleaning.

Acid cleaning is best used as a preventative measure to keep "hot spots" from developing into heat transfer issues. If your cooling water system is subject to calcium deposits, or you may have carbon buildup from hot oil systems, regular acid flushing is recommended to ensure good thermal performance and acceptable roll life.

Upgrading Services

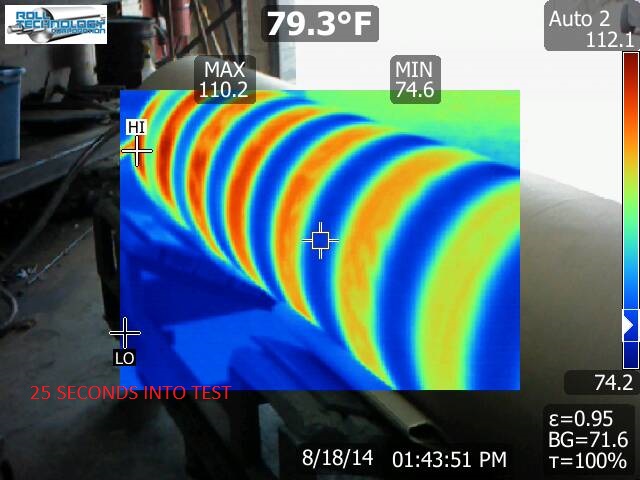

Roll Technology is constantly striving to improve its services and we have recently upgraded our acid cleaning heat roll service. We now take thermal imaging pictures of the rolls internals before flushing and after flushing - showing the difference in the rolls fluid flow. We have also added a vibrating technique while the roll is being flushed to further loosen the calcium deposits and/or carbon deposits and scale buildup.

It is critical that we receive the MSDS sheet from our customers to verify the fluid runs throughout their rolls. Certain materials do not mix with the acids we use and can cause fume problems along with waste treatment issues. We are constantly monitored by our local Regional Sewer Authority as to the materials we treat and dispose from our own system, in addition to the hexavalent chromium rinse water that is regularly treated.

To further effect a positive result in acid cleaning hot oil applications, we ask the customer to drain all the oil before sending the roll to us. We then thoroughly clean the roll with a hot soap solution designed to remove oil residue and expose the carbon buildup. Then, an inhibited acid is flushed through the inner flow channels for sometimes 3 and 4 days. In addition, the rolls are vibrated through the process with the idea of shaking loose carbon particles and debris. We also take thermal images before and after cleaning as well as flow meter readings before and after cleaning, all in an attempt to show improvement in heat transfer performance.

To learn more about Acid Cleaning, contact us today!

CONTACT US TODAY

Click HERE to request a quote or call us at 1.800.742.7655